GET STARTED

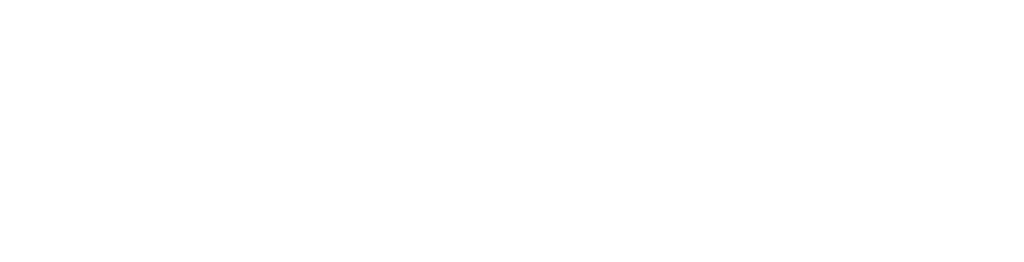

Enhancing Logistics with Autonomous Robots

LexxPluss aims to conquer all the challenges faced by the logistics industry, such as improving the working environment, securing manpower, and responding to increased demand. We offer a full range of services that are optimal for each logistics depot, from implementaion to continuous on-site operation.

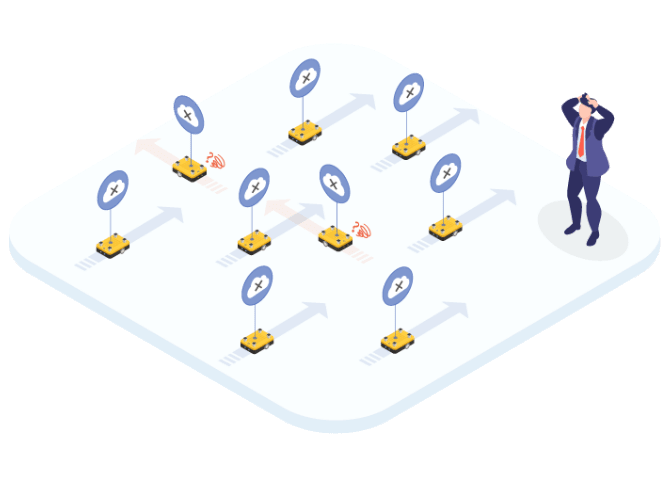

Problems with robots designed to follow pre-determined routes

Obstacles stopping the robot.

AGVs will get stuck on the spot and operations will come to a halt if an obstacle is placed on the route, as they follow a predetermined route.

No cordination between robots.

Operating multiple AGVs risks traffic jams and collisions, as they only perforn their tasks indivisually without any coordination.

No idea how to improve operations

It is difficult to determine the efficiency of a fleet of AGVs as they are not networked together.

LexxPluss Solution to Automated Logistics

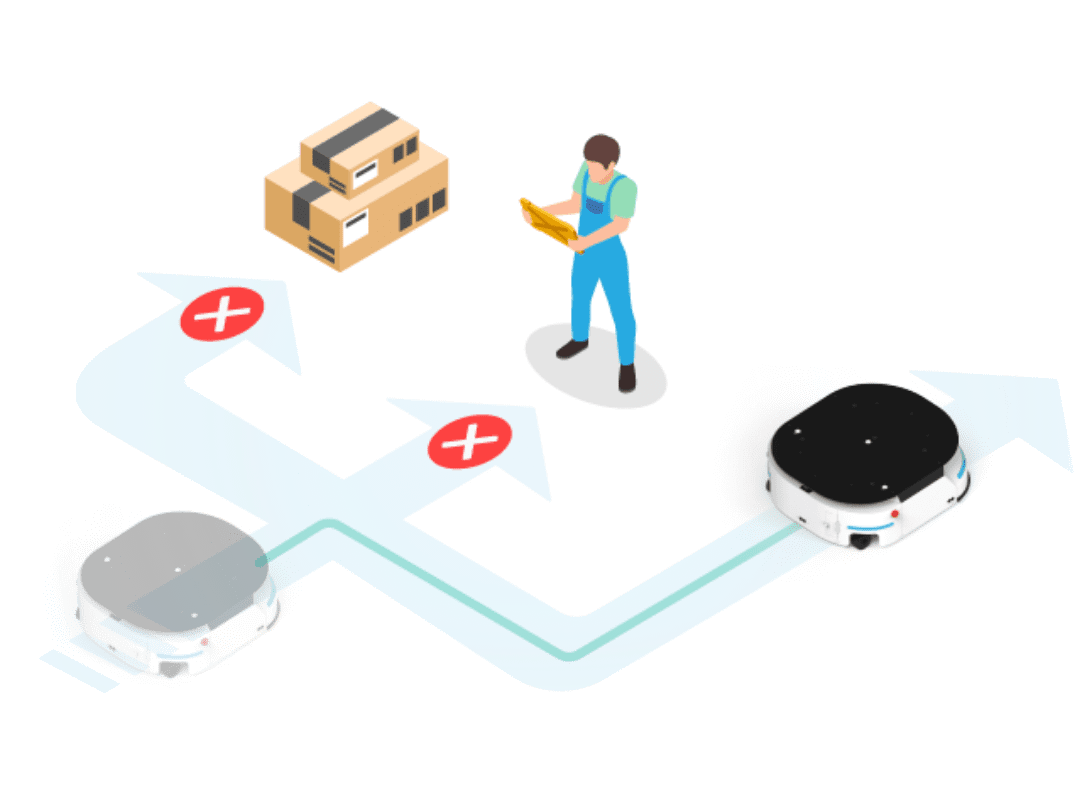

Robots Determine On-Site Conditions

LexxPluss' Hybrid-AMR uses autonomous driving technology to determine the best route to take at any given point, while assessing the situation on site. This allows the Hybrid-AMR to perform consistently even on places where operations are constantly changing.

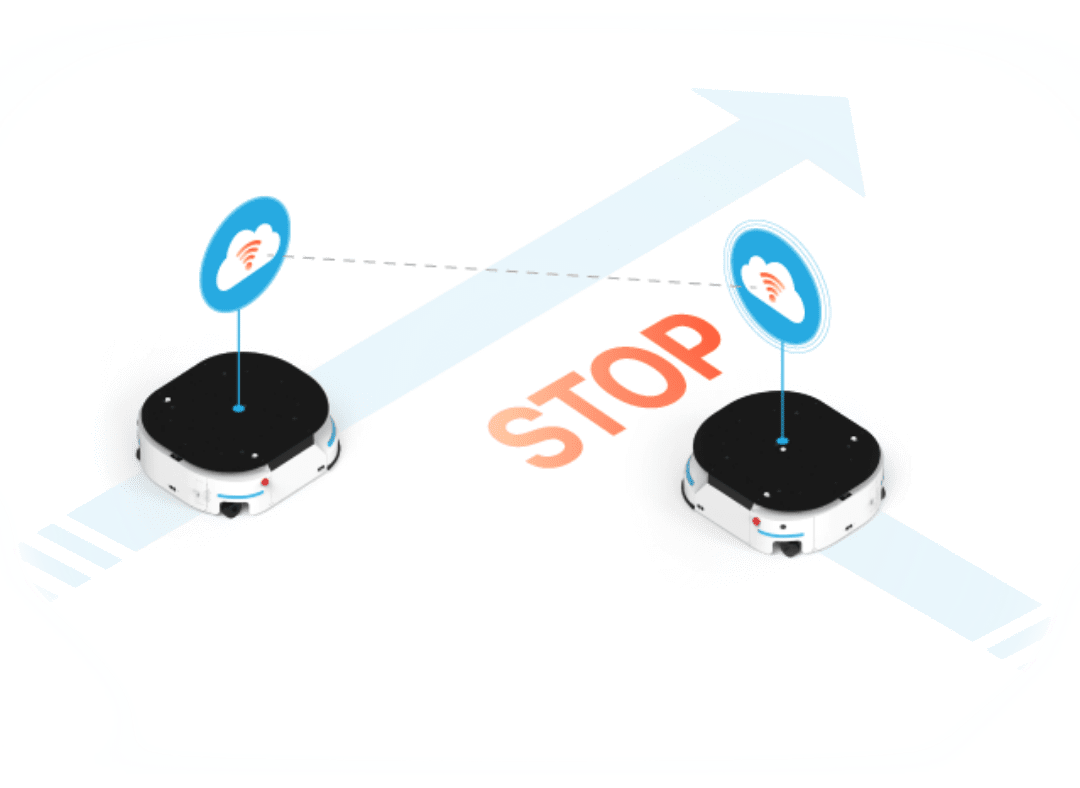

Centralized Management of Robot Status OptimizesThe Entire Fleet

The Hybrid-AMRs are managed by Konnectt, an integrated, centralized robot control system. This allows robots to give way to each other to avoid congestion, enabling the entire site to be continuously managed and optimized.

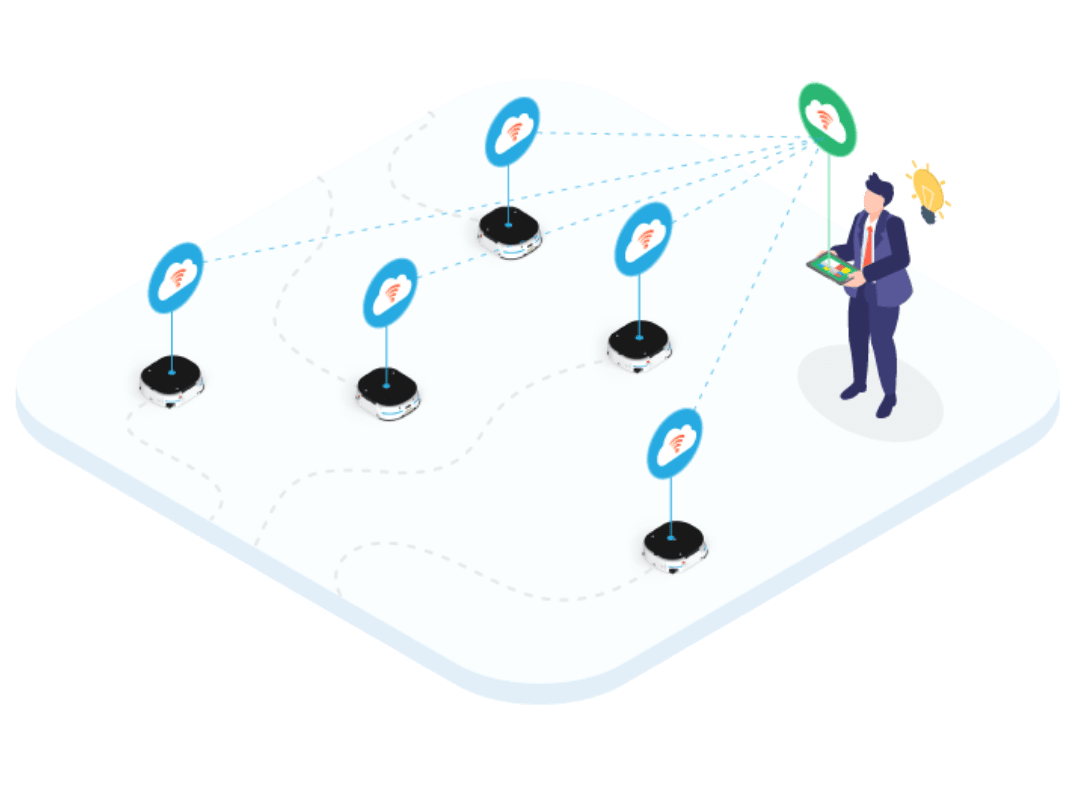

Smooth On-Site Improvements Based on Data

Konnectt collects and stores all kinds of data, including robot utilization rates, running conditions, and the number of errors. This allows for detailed analysis of on-site operations, facilitating operational optimization.

One Stop Shop for All Manner of Services

LexxPluss offers a full range of services necessary to build the next generation of distribution centers.

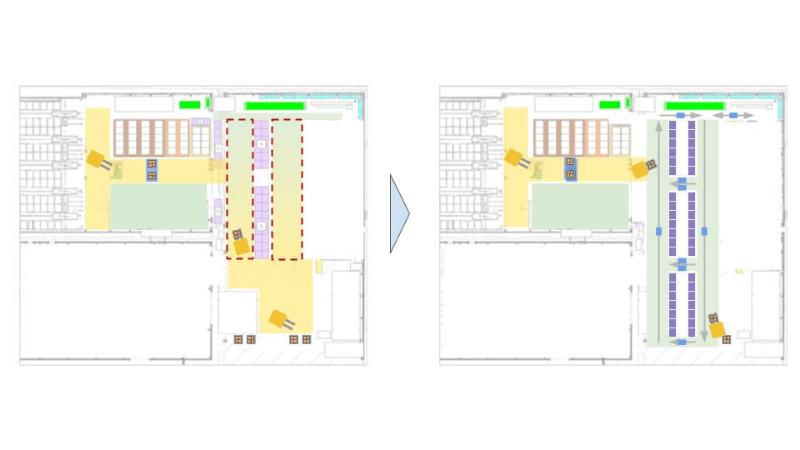

Flexible Adaption

Identify operational issues and possible improvements based on information from site layouts and on-site inspections.

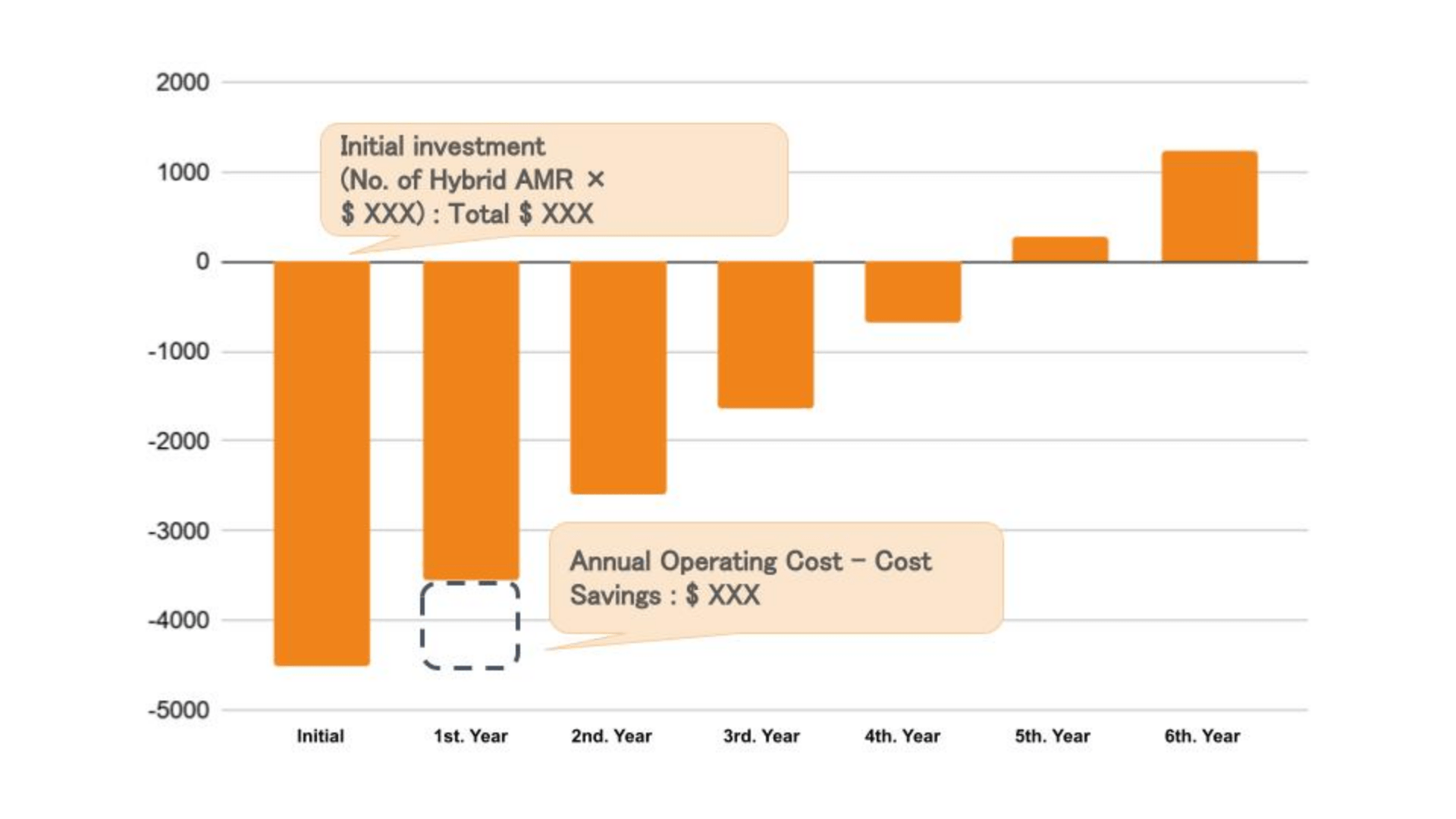

Effectiveness Analysis

We will verify whether Hybrid-AMR implementation is cost-effective based on the number of robots needed, the cost of integration, and the expected labour-saving effects.

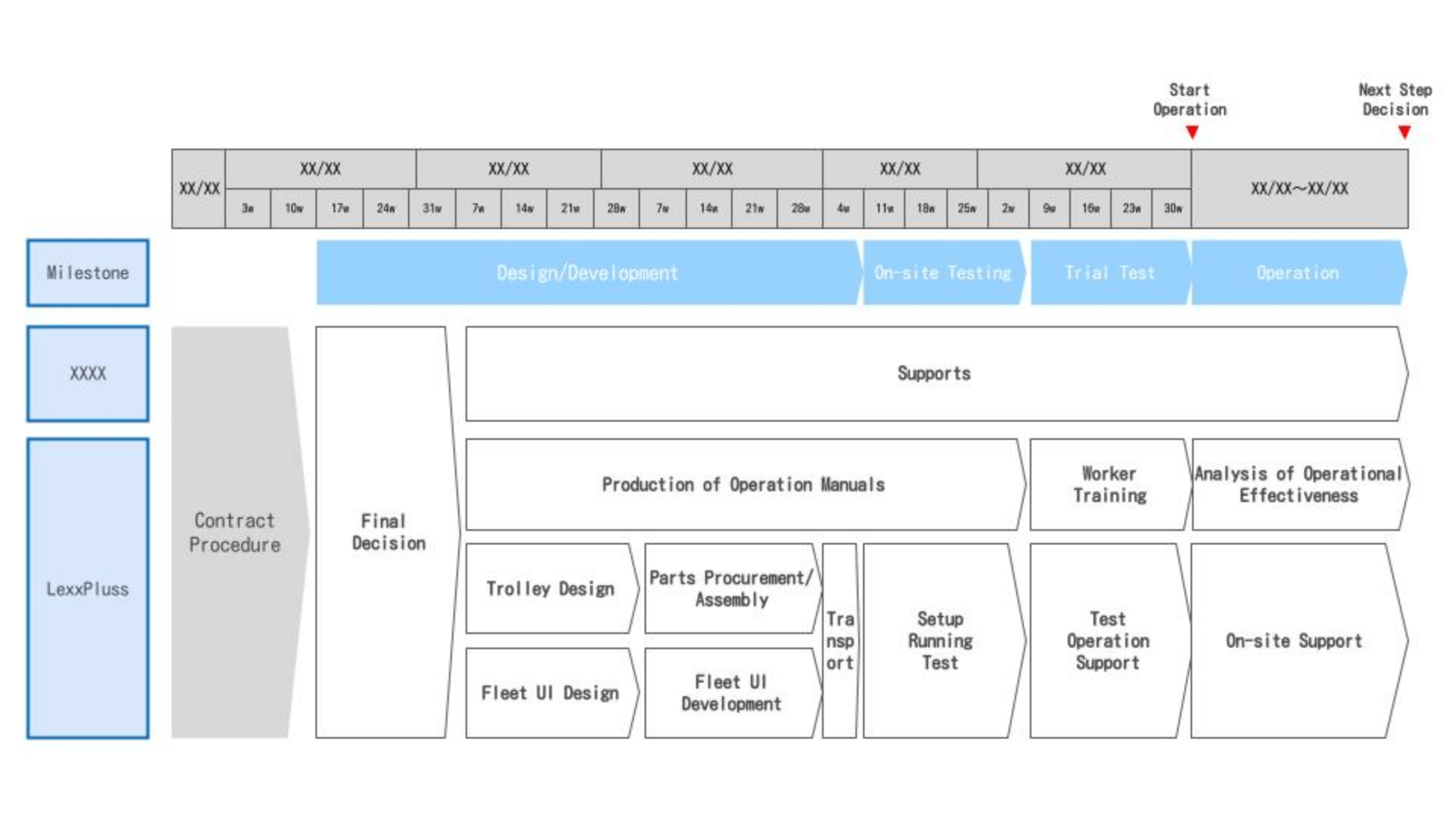

Start-Up Plan Assessment

We work in partnership with our customers to form logistics strategies, aiming to develop realizable milestones and schedules.

Contracts

For partners who are new to robotics, we will work together in forming contracts to make sure everyone gets what they want.

Cooperation with Trollies

We will design robots to automatically transport any trolley of your choosing.

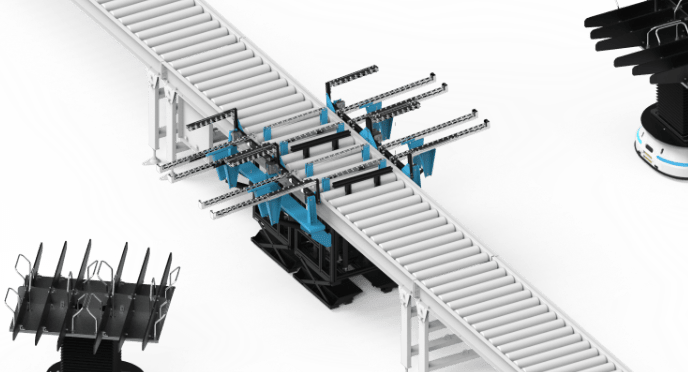

System Cooperation

System integration with elevators, conveyors and WMS can also be achieved via Konnectt.

Operational Design

We support our partners all the way, aiming to continuously improve on-site operations with upgrades and new ideas.

Maintenance and Servicing

We also provide maintenance and servicing during operation, proposing operation plans tailored to our partner's needs.

Operations Management

With Konnectt, the status on-site operations can be checked from anywhere.

Follow-Up Services

We will support you in every situation, whether you need help with troubleshooting or want to know how to operate the system.

Optimizing Operational Effectiveness

We will constantly analyze our robots using data collected from Konnectt to improve operations.

Our Solutions

Q&A

-

Q

What is the lead time from contract to start of operation?

ATypically 3-6 months. It may take longer to implement our solutions depending on the following

・The development required to integrate our solutions with existing infrastructure

・The availability of our Hybrid-AMRs -

Q

Is it necessary to purchase to the robot?

ANot at all! We can offer the product on a lease contract basis. Short-term rentals are also available.

-

Q

What do the initial costs cover?

AThe initial costs will cover the following

・Purchase or rental of the robot.

・Peripheral equipment such as carts, trolleys, tablets.

・Labor costs related to setup work at the installation site. -

Q

We have the robots, but do we need to pay for the operating costs?

AYes! Even with the robots, they won't operate without our Konnectt Robot Management System. The operating costs cover the following

・Running and optimizing the operation of our Hybrid-AMRs using Konnecctt.

・Maintenance and upkeep of the robot and related systems.

・Customer support. -

Q

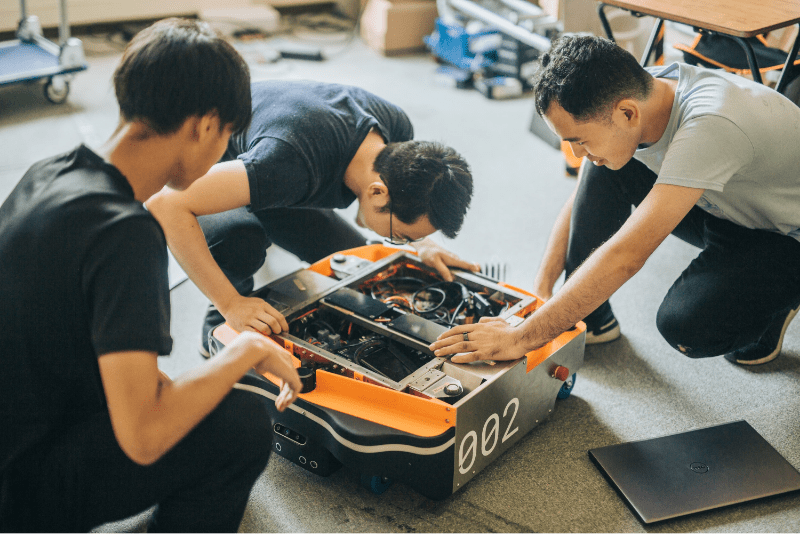

Is it possible to repair and maintain the robot in-house?

AYes! Maintenance and repair are optional add-ons in which our technicians will come onto your site to carry out repair operations. However, if you'd prefer to save on costs and maintain the Hybrid-AMRs yourselves, we will assist you and demonstrate how you can maintain them yourselves.

-

Q

What is the maximum number of units that can be installed at a single site?

AOur Konnectt Robot Management System allows for simultaneous operation of 50 robots. If operating a large site or on multiple floors, it is possible to install several fleets of robots with their own Konnectt systems, allowing for the operation of more than 50 robots.

-

Q

Is it possible to do a trial run with just a few Hybrid-AMRs?

AYes! We will respond to your needs based on your on-site operational status and mid/long-term logistics strategy. We can start small and work our way up to running larger fleets.