Hybrid-AMRBest of Both Worldsfor All Your Needs

Patented Hybrid-AMR technology for guaranteed Accuracy

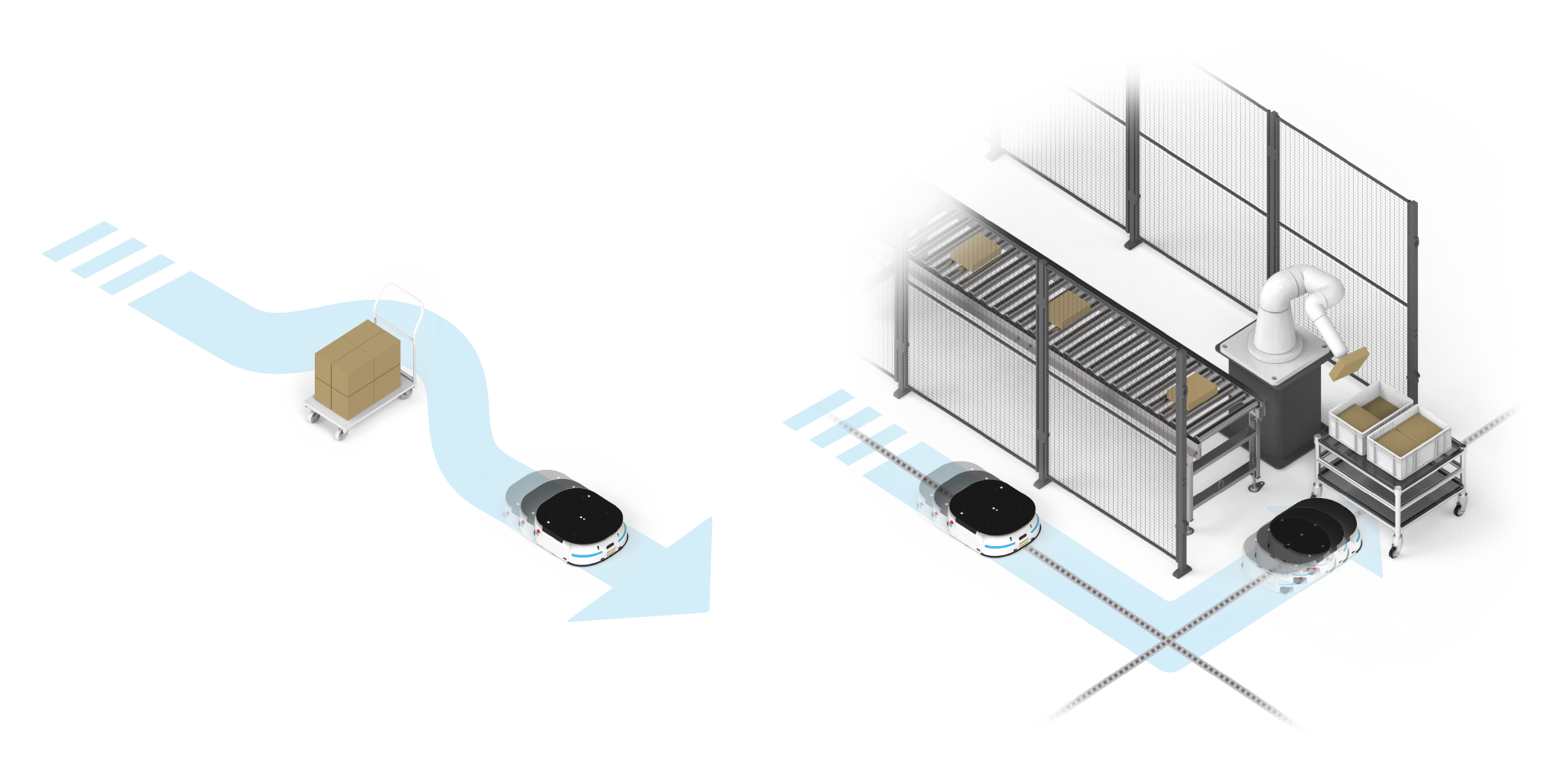

Cooperative System

The Hybrid-AMR system enables the robot to work in conjunction with assorting systems and conveyor belts for seamless transport of goods.

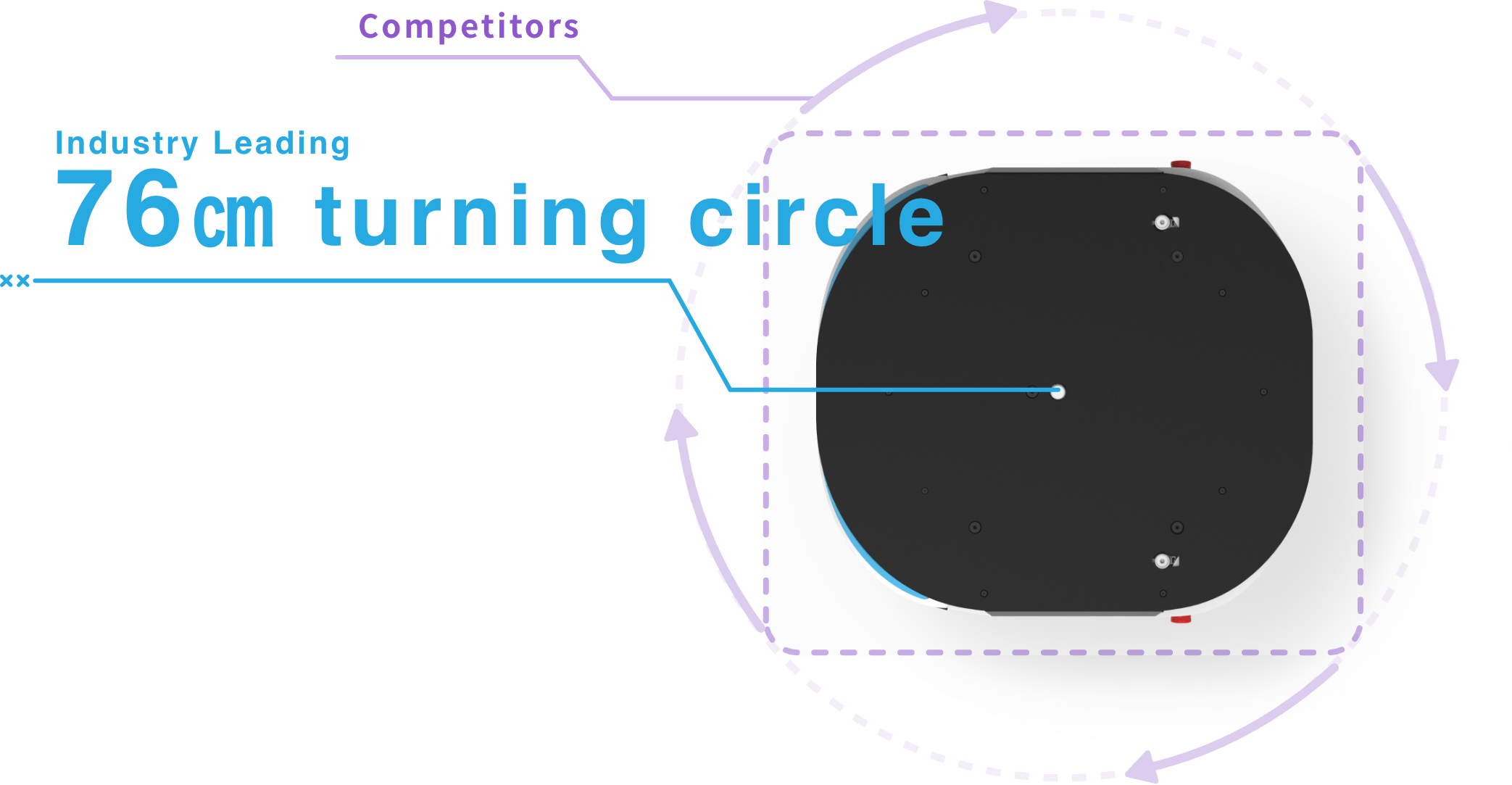

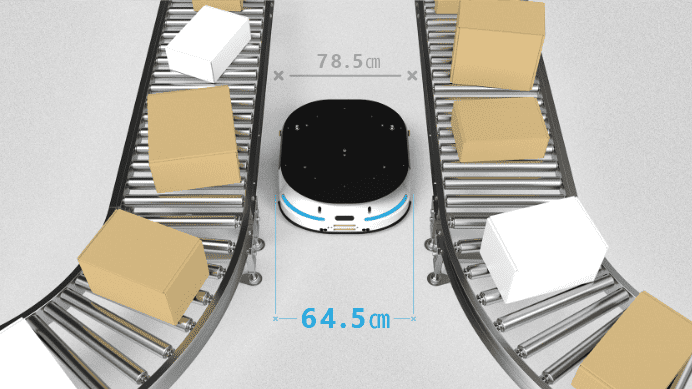

Navigation in Tight Spaces

Hybrid control allows for obstacle avoidance and safe operation in tight spaces, enabling the robot to operate anywhere and everywhere.

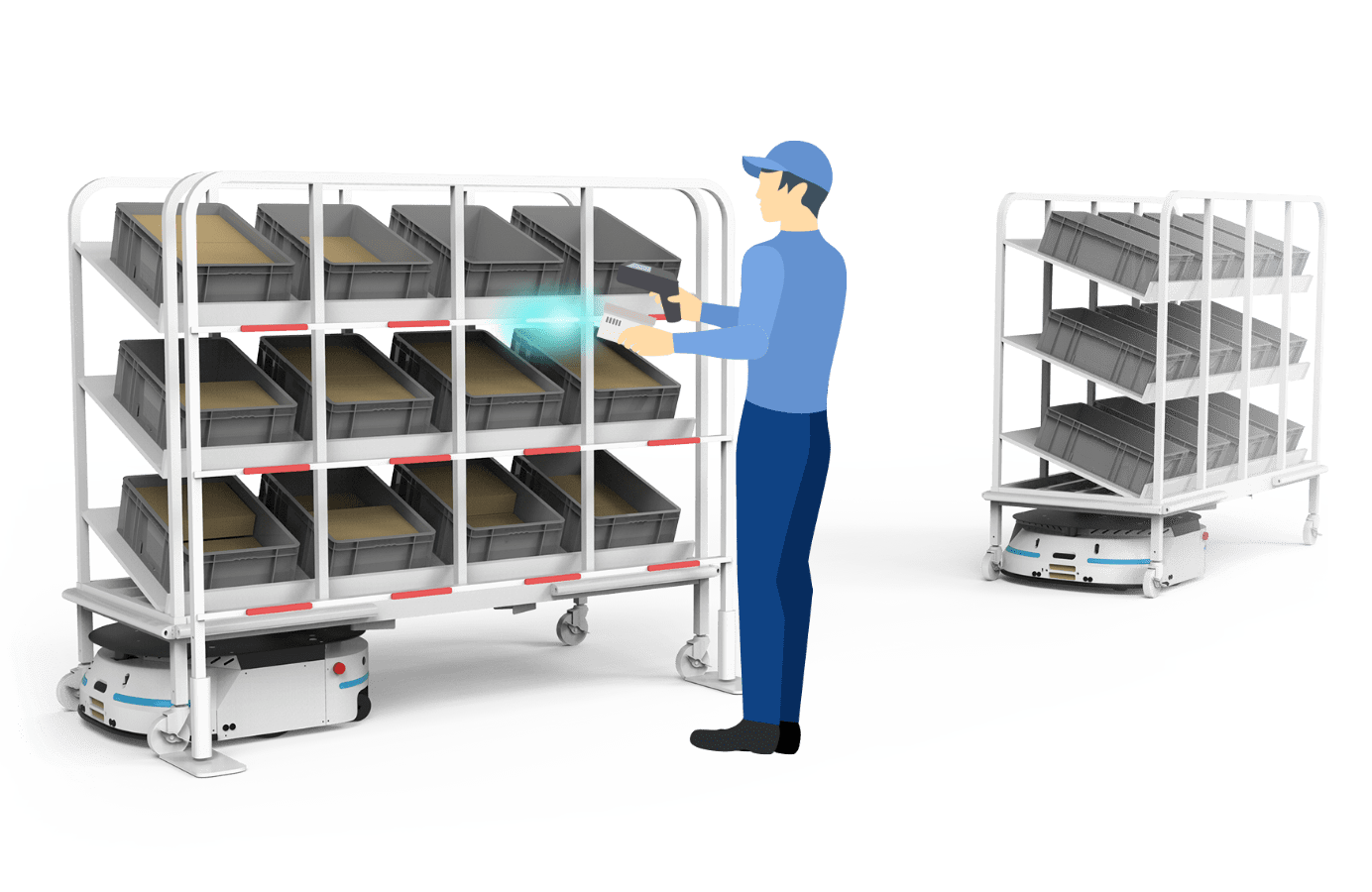

Quick and Automatic Connection with Trolleys

Hybrid-AMR functionality enables the robot to automatically link with a variety of trolleys, optimising the flow of goods without need for human intervention.

Safe Robot Operation

Multi-Sensor

The multi-sensor array enables the robot to detect humans and obstacles for safe on-site operation.

Trolley Contact Detection

The Hybrid-AMR's actuator sensors eletrically link the robot to any trolley it is carrying. The robot can communicate with bumper switches on the trolley, enabling it to stop on the spot in the event of a collision or towing failure.

Specifications

Hybrid-AMR

Specs

Size

707 (L) x 645 (W) x 228 (H) mm

Turning Radius

380 mm

Weight

76kg (167 lbs)

Navigation

AMR/AGV *1

Loading Weight

300kg (660 lbs)

Lifting capacity for objects is 100 kg (220 lbs) *2

Towing Weight

500kg (1100 lbs) *3

Communication

WiFi IEEE 802.11a/b/g/n

Sensors

LiDAR x 2 / USS x 5 / Visual Camera / IMU / Temp Sensors x 7

Operational Temperature

0 ~ 40 degrees

Cart Type

Customizable

✔

Roll Box

✔ No modification Required

6 Wheel Cart

✔ No modification Required

Pallet

✔

Safety

Alter device

Speaker / LED

Emergency Stop

Bumper / S-emergency Stop / E-Stop button / Software Braking System

*1 Hybrid AMR can operate in both AMR mode (autonomous driving) and AGV mode (tracked driving).

*2/3 It may vary depending on the loading direction, center of gravity position, and type of truck.

*4 Maximum speed is affected by the ambient environment, the material and condition of the traveling floor, and the load being carried.

Contact

Please feel free to contact us