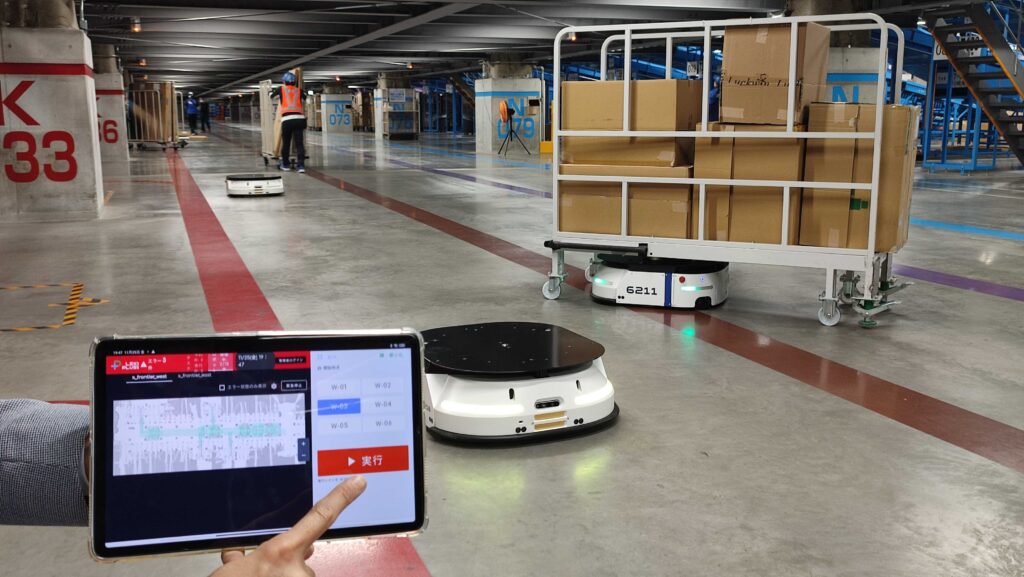

After the implementation, we received feedback from customers regarding both positive aspects and areas needing improvement. As positive points, they mentioned the ease of operation when starting the robots and task instructions on the tablet, as well as the excellent user interface that makes it easy to see the robots executing tasks and their current positions. Additionally, they appreciated the stable operation in handling transportation regardless of the volume or weight of the cargo.

On the other hand, there are strong demands for continued stable support systems, such as prompt responses and resolution of issues when problems occur. In response to these requests, LexxPluss will continuously improve its support system and response processes to ensure customers can use our services with peace of mind.

LexxPluss will continue to aim for further solving challenges in the logistics and manufacturing industries, which support Japan’s infrastructure