Automated Solutions and Intralogistics at the Ready

There is no commodity as precious in manufacturing as time. Processes must be sped up, unnecessary steps must be cut and above all, deadlines must be met.

We know this at LexxPluss which is why we offer automated solutions and intralogistics that align with manufacturing goals, fit into existing environment layouts, and enable customers to easily scale when needed.

Accelerate your Manufacturing Processes

In manufacturing, it’s often necessary for automation solutions, such as robots, to work with high precision. That’s why the Lexx500 can switch to AGV mode, allowing the robot to operate on guideways with an accuracy of approximately ±1.0 mm.

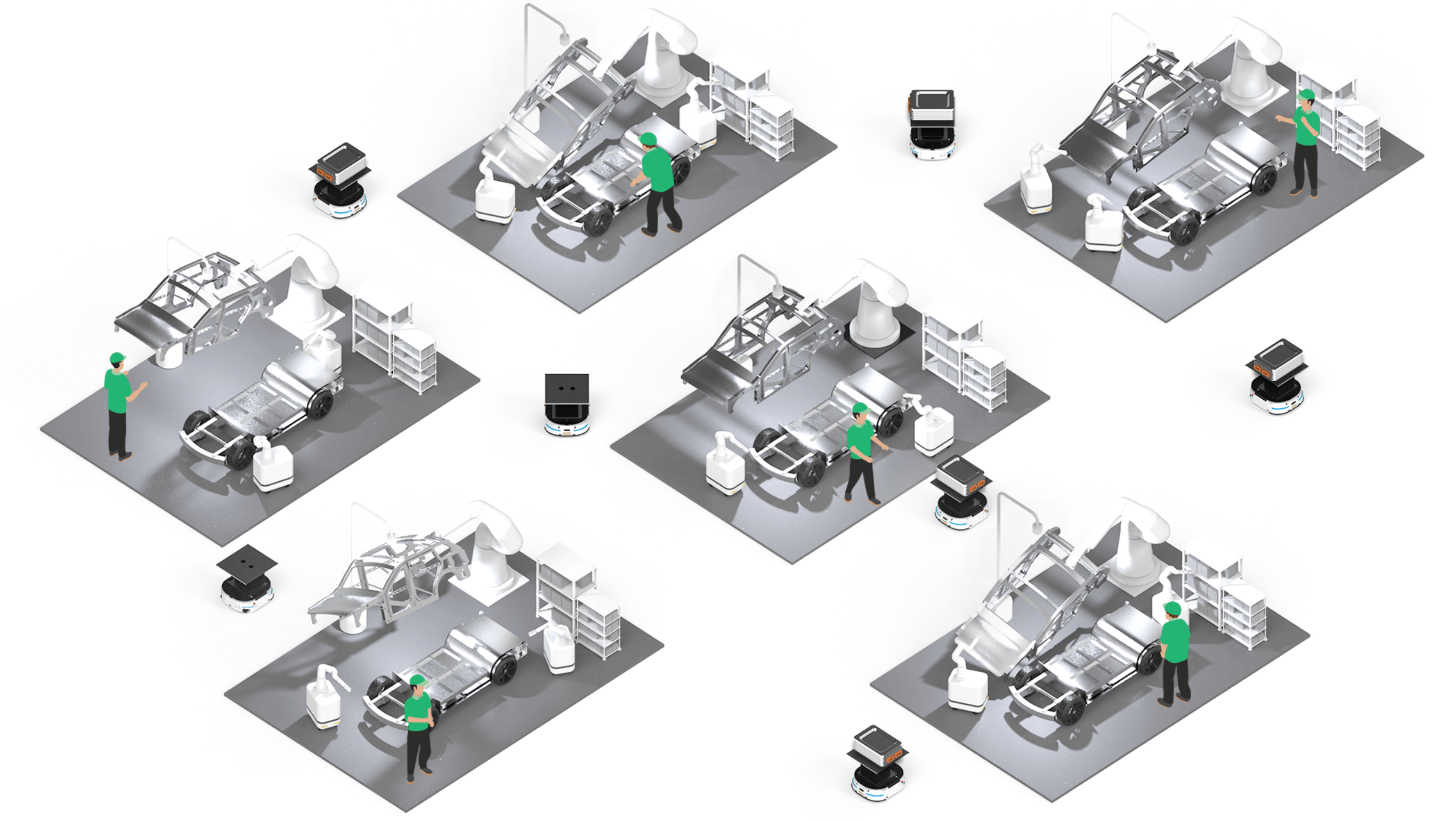

Maximizing Flexibility and Efficiency

This also allows it to work in conjunction with robotic arms and other op-mounted equipment. Furthermore, our Lexx500 supports combined native and mixed production setups, often a better option for BEV/EV manufacturing. This is called Flexible-cell Manufacturing (FCM) and it replaces conveyor belts that move, for instance, one car after another along the same assembly line with Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs).

These transport car bodies individually to the assembly workstations appropriate for that specific model of vehicle. With our automated manufacturing solutions, you can accelerate these types of processes and in turn, your output.

Accelerate your Manufacturing Processes

Relying on manual material transfer within a facility can significantly disrupt production flow. This not only leads to increased operational costs but also creates bottlenecks in scenarios with congested aisles or frequent changeovers between production lines.

Furthermore, dependence on elevators for movement between floors adds another layer of inefficiency to the process. LexxPluss’s AMRs can streamline these internal logistics, ensuring a smooth and uninterrupted flow of materials.

At LexxPluss, our products free staff from this arduous labor by automating cart linkage and obstacle avoidance during transport operations without burdening pre/post processes.

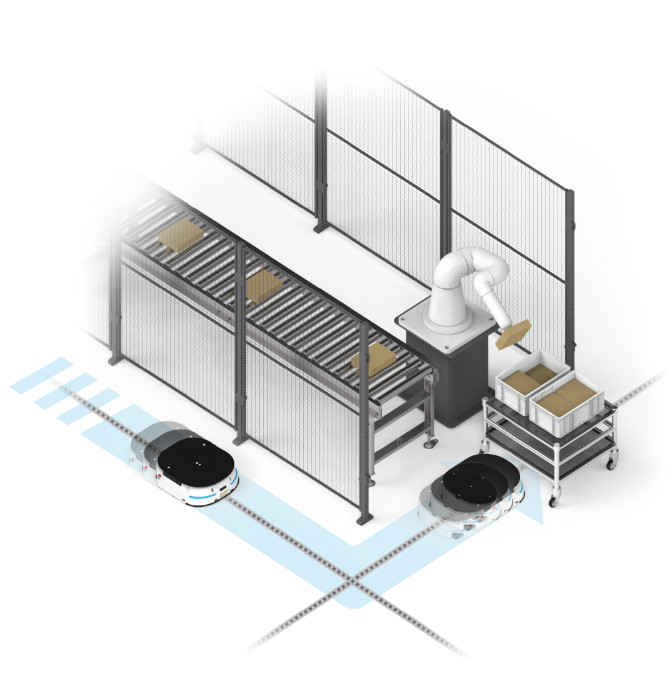

For instance, the Lexx500 system allows you to realize a flexible and effective loading operation instead of using traditional conveyor systems. The Lexx500 improves the burden of picking bulky and heavy items by assisting to pick such objects.

Beyond streamlining material movement, our solutions enhance overall production efficiency through seamless integration with SCADA and MES, and compatibility with various cart and trolley types. This includes the Lexx500’s ability to easily be equipped with various types of interfaces, allowing for autonomous handling of solutions that interact directly with conveyor belts, robot arms, etc., eliminating the need for manual intervention.